What we do

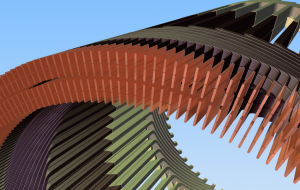

Traction motor coils

Our company has been well established for over 30 years on the market and we have been successfully producing traction motor coils. In recent years we have acquired unique quality and highly sophisticated products due to specialization and innovations in the process of development and production.

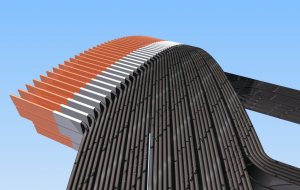

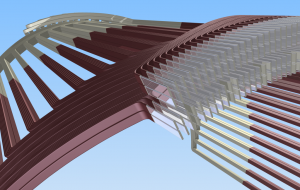

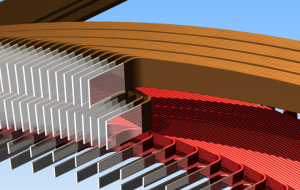

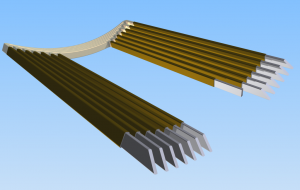

Digital prototyping – digital rewind

Digital prototype is an easy way to check the coil fit in the armature before the first conductor is cut. Digital rewind of armature allows to check the spaces between coils. Appropriate space which si required for easy coil insertion to armature, comes from experience with more than 30 different coil products, was designed by using 3D modeling software. The final 3D coil model after corrections is used for design of tooling we need for production. Manufacturing data comes from native 3D model.

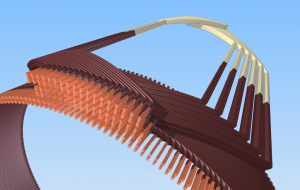

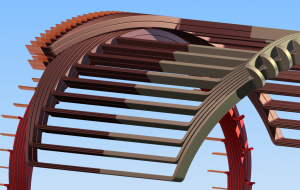

Prototype manufacturing, check and testing

During prototype manufacturing, all the tools are tested to produce an excellent bending and shaping of the conductors, without damaging the insulation. Corrections are made on tools to get excellent coil shape and continuous evolvents. Coils are checked in armature model. Spaces between coils are compared to CAD model of the winding. Behaviour of the coils during inserting into the armature model shows the next steps in the final coil tuning. The whole project is evaluated and our Know-How is improved.

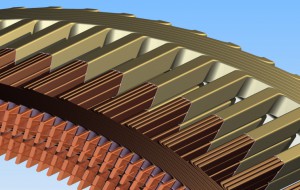

Value added coils

We supply Traction motor coils with excellent properties and geometry for faster and easier rewind of traction motor armatures. The use of our coils brings reduced rewinding time, increases quality of the rewind.

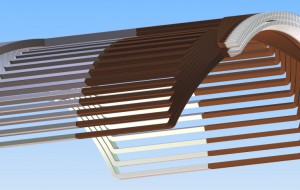

COIL SETS

Packed in paper boxes on a pallet, ready to ship, easy storage, directly to armature rewind stand.

Our products

We are currently able to produce the following types of armature windings for traction motors and generators

TE005, TDM5003, TE006, genTD802, genTD804, genTD805, AL4542FiR, AL4846zT, AL4446iP, MT4433-4, T910, AD4346gT

T910 DC traction motor armature coils

coils

AD4346gT DC traction motor armature coils

coils

AL4446iP DC traction motor armature coils

coils

TE051 DC traction motor armature coils

coils

AL4846zT DC traction motor armature coils

coils

AL4542FiR DC stator compensation winding

coils / stator

TD805 DC generator armature coils

coils

MT4433-4 DC traction motor armature coils

coils

TDM5003 340kW DC traction motor armature coils

coils